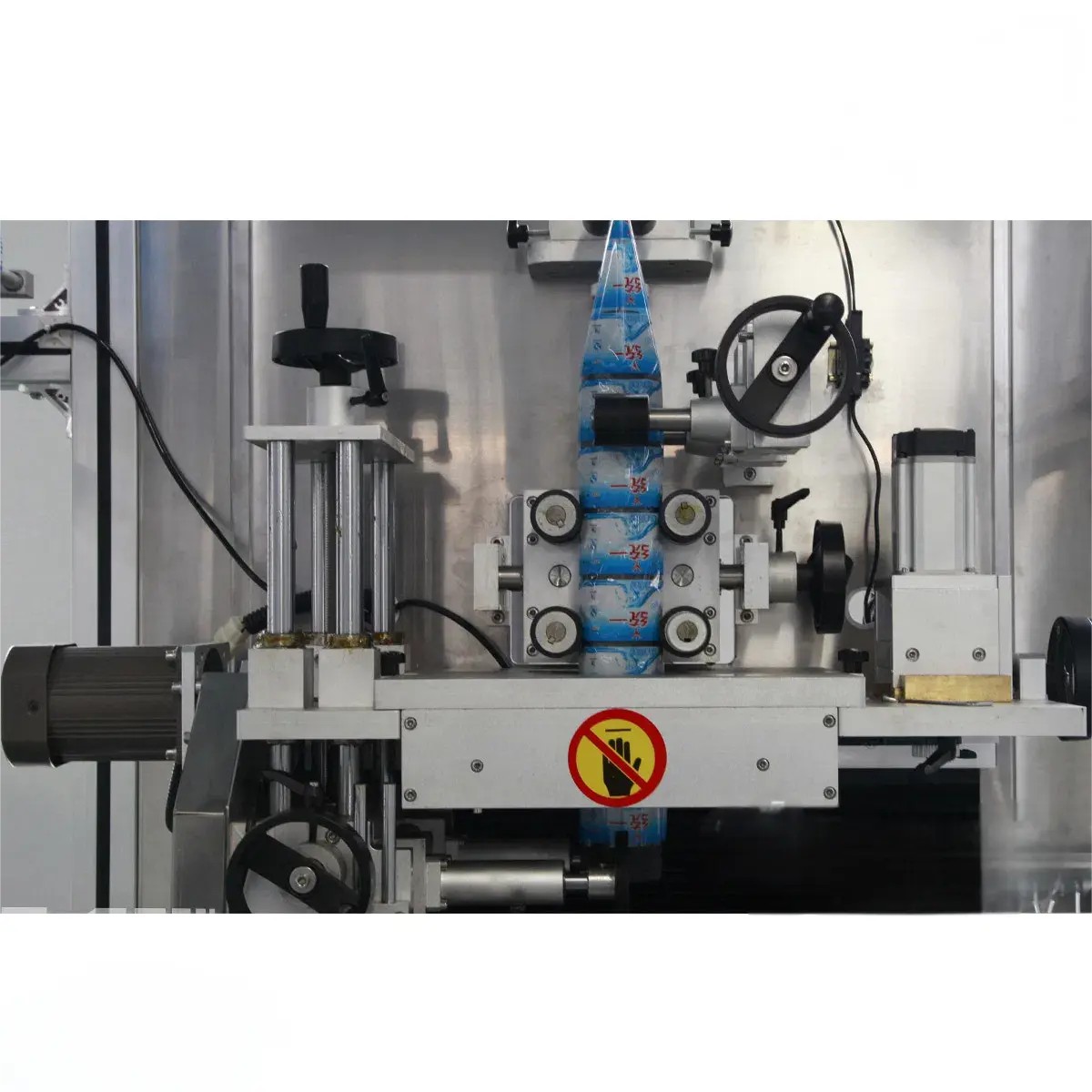

Automatic Plastic Water Juice Bottle PVC Label Sleeve Heat Shrink Labeling Machine

Automatic PVC Sleeve Heat Shrink Labeling Machine

Introduction:

This shrink sleeve labeling applicator function is for PVC label shrink on the bottle ,used for beverage bottle package solution ,international advanced technology ,cover the circle label on PET bottle ,And then hot shrinking to fix on the position which bottle body designated.

Product Description:

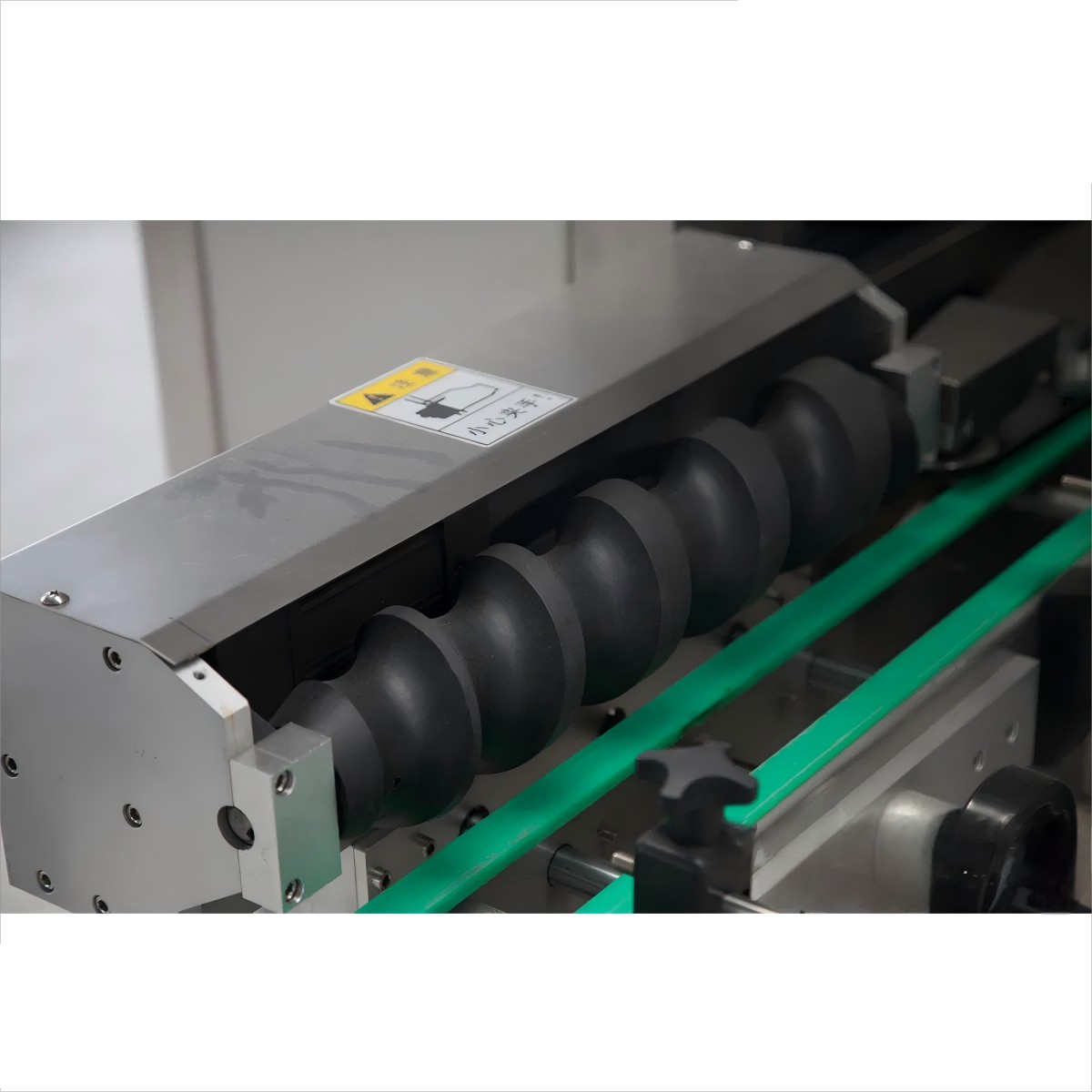

The machine's structure is compact,and suitable for the production line of different direction and different height ,The machine part adopts combination designing of modularization ,and make the machine reasonable ,the height adjustment adopts motors fluctuating,it is convenient to replace the material ,The special cutter head designing ,make the film rolling cut more exactly and reliably.

Technical parameter:

| Model | SLM-150B | SLM-250B | SLM-250D |

| Labeling heads | 1 | 1 | 2 |

| Capacity (500ml/bottle/min) | 0-150 | 150-250 | 150-250 |

| Rated Power | 2KW | 2.5KW | 3.5KW |

| Suitable Bottle Diameter | φ48-96mm | ||

| Suitable Label Height | 30-250mm | ||

| Label Thickness | 0.03-0.13mm | ||

| Applicable internal diameter of paper tube | 5"-10"mm(Adjustable) | ||

| Machine Size | 2000*850*2000mm | 2000*850*2000mm | 3000*1200*2070mm |