Solution for Can Beverage Filling Packaging Line

Solution For Can Beverage Filling Packaging Line

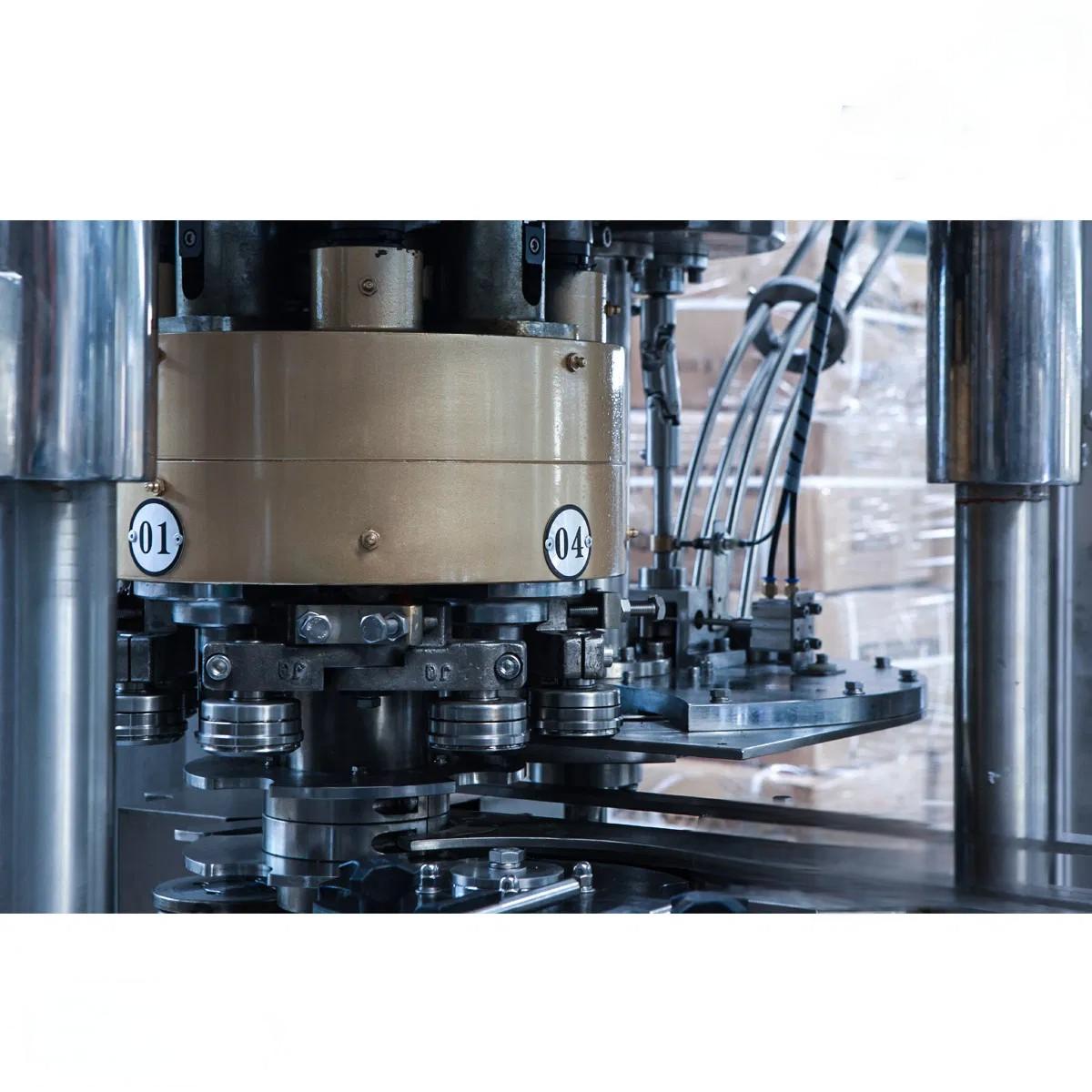

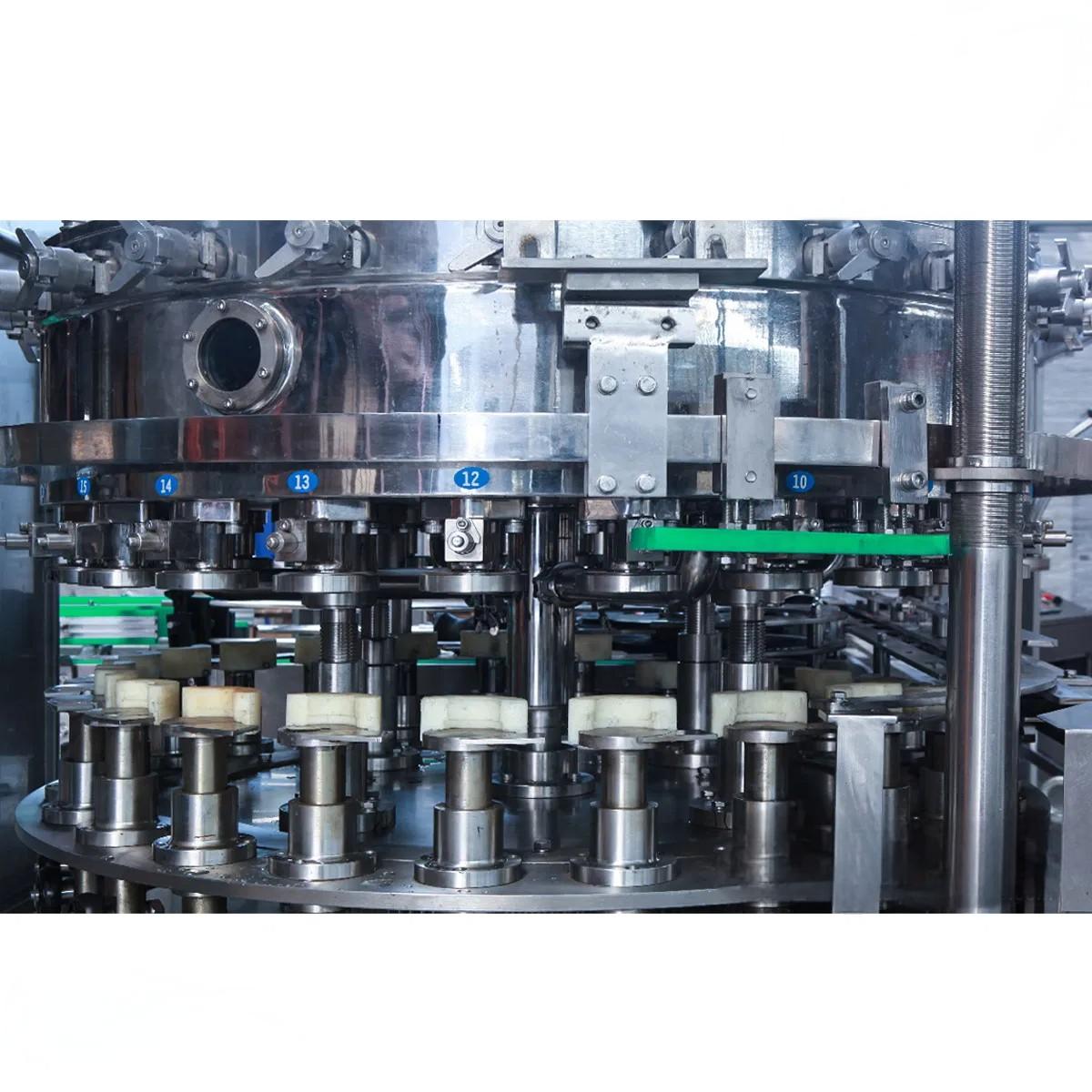

* we provide the complete pop cans / tin can filling and package solution ,from can depalletizer ,can rinsing machine ,can filling & sealing monoblock machine ,leakage check,liquid nitrogen dosing machine ,pasteurizer tunnel ,blow dryer ,carton package ,film package system ,which is widely used for the beverage ,beer ,juice industry and so on

| Technical parameter :can beverage filling line | |||||

| Model | GDF12-1 | GDF18-4 | GDF24-4 | GDF32-6 | GDF40-8 |

| Capacity(cans/hour) | 2000 | 8000 | 12000 | 15000 | 20000 |

| Suitable container | Aluminum Can / Tin Can / Plastic Can | ||||

| Can diameter | Dia50 ~ dia99mm | ||||

| Can height (mm) | 70-133mm | ||||

| Compressor air | Isobaric filling / normal pressure filling | ||||

| Application | Beverage Can Filling Machine | ||||

| Total power (kw) | 2.4kw | 4.4kw | 5.2kw | 6.2kw | 7.2kw |

| Overall dimensions | 2.5*1.9m | 2.8*1.9m | 3.2*2.15m | 3.5*2.5m | 3.8*2.8m |

| Height | 2.3m | 2.5m | 2.5m | 2.5m | 2.5m |

| Weight(kg) | 2500kg | 3200kg | 4000kg | 4500kg | 6500kg |