Case 1: Revolutionizing Bottled Water Packaging

Client Need: A well - known bottled water brand aimed to increase production capacity by 30% while reducing packaging costs and enhancing product sustainability. They required a comprehensive packaging solution that could handle high - speed production and accommodate eco - friendly packaging materials.

Alps Machine Solution: Alps Machine designed and installed a custom - built filling and capping line. The line featured high - speed filling heads capable of filling 1,200 bottles per minute, significantly exceeding the client's production target. To meet sustainability goals, the line was engineered to work with lightweight, recyclable plastic bottles. Additionally, an advanced leak - detection system was integrated to ensure product quality.

Results: Within six months of implementation, the client achieved a 35% increase in production capacity. Packaging costs were reduced by 20% due to optimized material usage and energy - efficient machinery. The brand also received positive feedback from consumers for its more sustainable packaging, enhancing brand reputation.

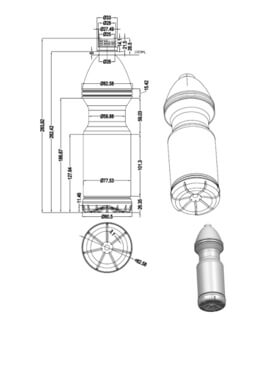

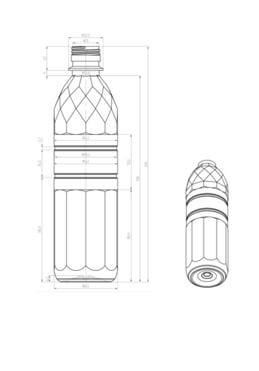

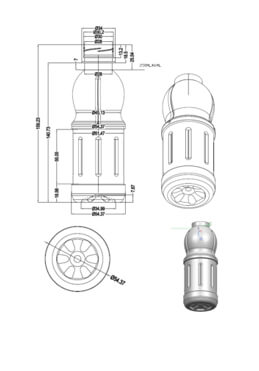

Customer Designs

|

|

|