Case 3: Streamlining Dairy Product Packaging

Client Need: A large - scale dairy manufacturer sought to upgrade its packaging line for milk cartons to improve hygiene standards and reduce downtime. Their existing system was prone to mechanical failures and did not meet the latest industry sanitation requirements.

Alps Machine Solution: Alps Machine proposed a turnkey solution that included a new carton filling and sealing machine made from food - grade stainless steel. The machine was designed with easy - to - clean surfaces and quick - release components for efficient sanitation. An automated monitoring system was added to predict potential mechanical issues and schedule preventive maintenance.

Results: The dairy manufacturer saw a 70% reduction in unplanned downtime due to equipment failures. Hygiene levels improved significantly, meeting and exceeding international dairy packaging standards. The overall production output increased by 25%, enabling the company to meet growing market demands.

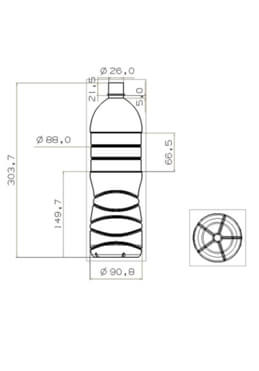

Customer Designs

|  |  |